The R.V.Parankar College of Engineering And Technology also offers Full time Graduate Program in Mechanical Engineering creates a community of top-notch scholars by bringing together faculty members which will establish graduate students with a common interest in innovation, creativity, and advanced professional study. Through the curriculum, our department strives to prepare our undergraduate students for careers in traditional Mechanical Engineering fields as well as careers in cross-disciplined areas in academia and industry.

We also pride ourselves on our faculty’s who guide to each student at exam as well as industry point of view ; Thermal and Fluid Sciences, Materials and Manufacturing, Mechanics and Systems and Controls.

The best way to learn more about Mechanical Engineering at Texas A&M is

We hope to see you soon!

VISION

The Mechanical Engineering Department endeavors to be recognized globally for outstanding education and research leading to well qualified engineers, who are innovative, entrepreneurial and successful in advanced fields of mechanical engineering to cater the ever changing industrial demands and social needs.

MISSION

The mission of the Department of Mechanical Engineering is to serve the students of Texas A&M University, the State of Texas, and the nation by:

• Providing quality education that is well-grounded in the fundamental principles of engineering, fostering innovation, and preparing students for leadership positions and successful careers in industry, government and academia.

• Advancing the knowledge base of mechanical engineering to support the competitiveness of existing industry and to spawn new economic development in Texas and the nation through active involvement in basic and applied research in a global context.

• Providing professional development opportunities for practicing engineers through continuing education, service, and outreach activities.

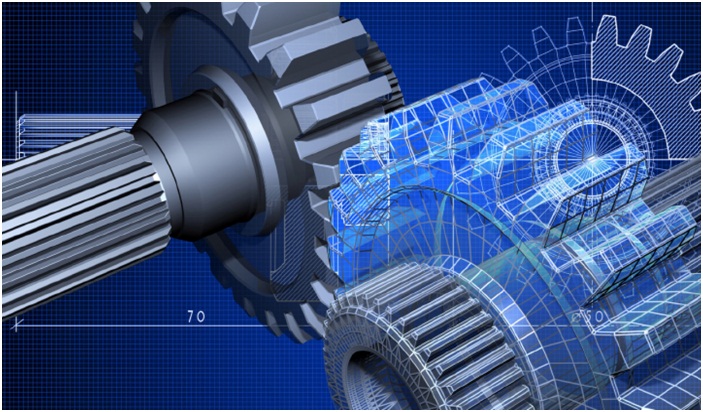

Our Lab:

Fluid Machine Lab: